Product 04.Water and Waste management systems

Water Treatment

Advantages

- Variety of cost-effective standard models

- Advanced selection software for optimal configuration

- Improved aesthetics and rugged design

- User-friendly, low maintenance and easy to install

- Versatility in applications

- Simpler distribution and collection systems

- Pre despatch assembly check

- Quick availability

Operating Range

Cooling Capacity100 – 1000 TR ( 350 – 3500 kW)

Chilled Water

Lowest outlet temperature: 5 degrees C

Chilled water delta T – 30 degrees C max.

Driving Heat Source

Steam (Pressure: 10 – 25 bar.g, Dry saturated) or Hot Water (Inlet temperature: 190°C – 225°C)

Effluent treatment, Recycle and zero liquid discharge

We provide effluent treatment solutions for various types of industrial wastewater. Customized systems to suit the wide variety of effluents and to maintain efficiency are provided to industries – systems based on Physico-chemical and biological treatments and membrane separation are offered to suit efficiency. We have the experience and capability to design and commission a host of clarifiers, filters, aeration, coagulation and settling systems for waste from industries like chemicals, drugs, pharma, refineries, leachates, etc.

Recycle and reuse of treated effluents is profitable in the ever-deteriorating environment of water scarcity. Reverse osmosis, ultra-filtration systems, and other tertiary treatment processes make this possible for industries keen on resource optimization.

Complete Solution availability list

- High COD effluent & High TDS effluent

- Difficult to degrade effluent

- Coke oven effluent treatment

- Color removal from treated/partially treated effluent for recycle/disposal

- Nutrients (Nitrogen, Phosphorus) removal

- Heavy metals, Cyanide, Fluoride removal

- Tailor-made industry-specific solutions

Waste water/ Effluent treatment solutions

- Industrial Effluent treatment & Recycle plants

- Sewage treatment& Recycle plants

- Zero Liquid Discharge (ZLD) plants

Sewage treatment & Recycle plants

BioCask is the most efficient state-of-art technology for domestic wastewater treatment. The innovative design of the BioCask has overcome all the limitations of conventional wastewater treatment systems. The BioCask uses a first-of-its-kind unidirectional fluidization pattern that makes efficient use of oxygen that is required for the biological degradation of organic impurities. The novel design of the aeration system in the BioCask also reduces the operating cost of the treatment.

Features

Can be install in 3.5 m clear height basement

Achieve BOD at outlet < 5 without Ultrafiltration

Minimum Civil Work

Can be Containerized for Aesthetic look

15% to 20% Turn Down

Low sludge production Modular design

Minimal operator interface

Aesthetically appealing

Flow : 50, 100, 150, 200, 250, 300 KLD

Desalination

With the rising cost of freshwater and its growing scarcity, economic treatment of seawater treatment offers the possibility of bridging the demand-supply gap.

Thermax designs seawater reverse osmosis for effective and efficient desalination. Desalination involves removing dissolved minerals from seawater and brackish water (a mixture of freshwater and ocean water) and is an increasingly important source of fresh water.

We have a number of successful installations that also incorporate energy recovery systems to improve the returns from the system. Thermax has supplied one of the largest seawater desalination plant to a leading chemical manufacturer

Containerized Plants

We provide state of the art tailor-made Containerized Ultrafiltration and RO System of which can be easily transported and protected from extreme environmental conditions.

Our containerized unit houses a robust steel box-frame which is suitable for mobility Pressure tubes loaded with RO membranes

Alarm and shut down functions ensure that the system is fail-safe

PLC mounted panel for auto operation

Each unit comes with flange connections for feed, permeate and reject and can be integrated with level controls

Advantages/Benefits

Quick installation

Fully automatic system

Minimal Site/Civil Work

Aesthetically appealing

Protection from the external environment

Efficient space utilization by the compact installation

Minimum operator attention for maintenance and service

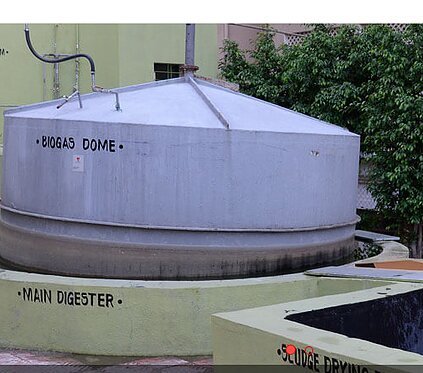

Solid waste treatment

Bioenergen is a plant used for processing biodegradable waste (kitchen waste, waste food, vegetable refuses lawn cuttings, dry leaves, plants material, etc.) in an environment-friendly manner to generate Biogas.

It is seen as the most favored option to deal with organic biodegradable solid waste since it enables the generation of nutrient-rich fertilizer and produces fuel in form of Biogas.

It offers an excellent alternative for decentralized processing of solid biodegradable waste and avoids the contamination of landfill sites.

These units are standardized and are in compact in size.

Capacities:

250-3000kg/day

Advantages/Benefits

High biogas yield and high purity methane content

Waste to Energy generation in the least processing time

Nutrient-rich manure can be generated for landscaping and gardening

Zero garbage and Zero-energy process

Eliminates dumping yard spaces

Maintenance of Hygienic environment

11 years of Accumulated trust

Request a Price Quote

Let us know your requirements and we will get back to you with the quotation as soon as possible.