Product 05. Air Pollution Control System

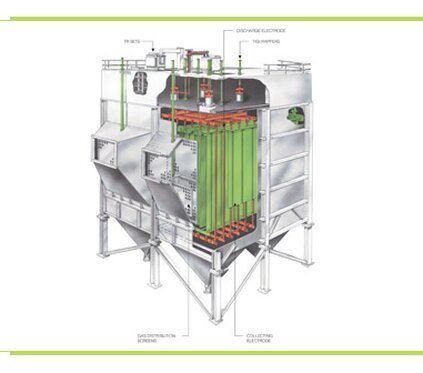

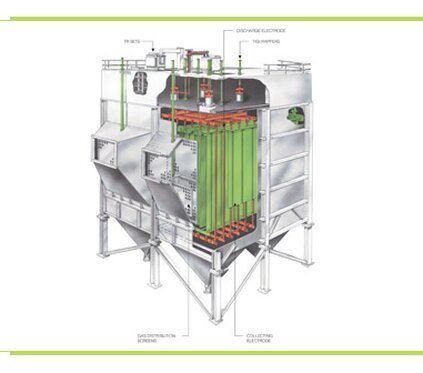

Electrostatic precipitators

An electrostatic precipitator (ESP) is a particulate collection device that removes particles from a flowing gas (such as air) using the force of an induced electrostatic charge. The charged particles are attracted to and deposited on plates or other collection devices.

The collectors (and emitters) are shaken by suitable mechanisms to dislodge the accumulated dust, causing it to fall with the force of gravity to hoppers below. The dust is then removed by a conveyor system for disposal or recycling.

Anatomy

- Horizontal and Vertical Flow Precipitators

- Dry type design for Gas volumes 5000 Am3/hr to 30, 00000 Am3/hr

- Wet type design for maximum particulate removal

- Hot gas designs for operation at temperatures above 450 Deg. C

- Expertise of Top as well as bottom rapping

- Diverse applications like corrosive gas, Over 100 types of dusts, tar etc

Bag filter

Plus jet Bag Filters & Reverse Air Bag Houses

Contact us for more details.

Since inception, Thermax ( Our associate company) has been engaged in the design and manufacture of fabric filter systems with different configurations, to suit different applications. Our product range today covers Pulse Jet Bag Filters and Reverse Air Bag Houses, both structurally supported freestanding on-line and modular off-line type units, including insert-able type units.

The pursuit of quality is especially important in fabric filter systems – where attention to application engineering, design detail and quality of fabrication can mean the difference between outstanding performance and mediocre, high maintenance service.

Complementing our dedication to quality, is the many years of operating field experience, spanning over 7000 installations, covering more than 30 different types of dust, for serving a variety of process applications like mills, kilns, furnaces, boilers, etc. or any de-dusting requirement.

The dustomat technology behind our products is absorbed from two world leaders – Zurn and General Electric. All this makes us uniquely qualified to serve any fabric filter requirement.

Operating Range

Outlet Emission

< 5mg/Nm3

Volume handling

1000 – 3500000 M3/hr

Wet scrubbers

We have been in the field of scrubbers’ right since the inception of Enviro Division. We offer scrubbers for particulate as well as gaseous pollutants and offers a wide range of scrubbers like

Venturi scrubbers and cyclonic scrubbers for particulate Capture

Open Spray Towers, Tray Towers and Packed Bed Towers for gas scrubbing

Advantages

Wide range of Scrubber design to cater to different types of particulate & gaseous pollutants

Customized design according to customer requirement

Hospet Wide choice of materials such as CS, stainless steel, Rubber Lined, FRV/FRP, Hastelloy, etc

Can provide flange to flange equipment as well as turnkey solutions

Have supplied FGDs with different absorbents such as limestone, Hydrated Lime, caustic, Soda Ash, Zinc Oxide, etc., handling inlet SO2 loads as high as 2% & outlet emissions as low as 15 ppm

Expertise to integrate the systems with upstream as well as downstream processes

Hand on experience of providing flue gas desulphurization (FGD) systems from small industrial boilers to large process plants

combo filters

ComboFilter, an innovative technology that can help aging pollution control equipment meet stringent environment norms.

Several Industrial units – cement, steel and power plants – had installed Electrostatic Precipitators (ESPs) for emission control. These systems had been designed for earlier emission norms of about 150 mg/Nm3. the revised norms for Pollution Control Boards are at a stringent level of about 30 mg/Nm3. In addition, industries also have to deal with changes in process inputs, inferior quality coal and increase in capacity which causes higher pollution. Installing a new ESP is costly and in most of the cases unfeasible due to limited space available in the plant. Add to these the costs of long shutdowns and production loss.

ComboFilter, the new technology from Thermax’s Enviro Division overcomes these problems by retrofitting old ESPs. Some of the ESP fields are converted to fabric filter thus combining the functions of an ESP and a bag filter.

The existing installation is fully used and no extra space or civil work is needed. And there is no need to modify gas inlet and ducting. Shutdowns are minimized to 45 days and lower and dust emission is reduced to about 10 mg/Nm3. For industries like cement, the product achieves futuristic environment norms and product recovery.

modular gas cooler

The modular gas cooler is a bare tube, shell, and tube type heat exchanger widely used for cooling down hot gases before entering bag filter.

It is arranged in a unique downflow entry arrangement with gas flowing inside the tubes.

Ambient air, which is used as a cooling medium, is blown over the tubes by ventilators / axial flow fans. The fans are controlled to ensure required cooling at optimum fan power.

Features

Some of the special features incorporated in the Thermax Modular Gas Cooler to increase efficiency, reduce wear & minimize maintenance include:

To address fouling due to sticky dust

- Use of large Diameter tubes to avoid solid build up inside the tube

- Use of optimum gas velocity inside the tubes to prevent dust setting down

- Use of straight tubes without any bends to avoid chocking

To resist erosion from abrasive dust

- Use of special replaceable tube inserts to prevent erosion due to gas turbulence at tube inlet

- Optimum flue gas velocity to minimize erosion based on Thermax’s experience in handling abrasive dust like Husk dust which contains more than 90% silica

To minimize leakages of air/gas

- Use of Thermax’s proprietary sealing system at free end to securely seal Tube to Tube Sheet joint

Divided into several smaller cells

- The TMGC’s modular design allows us to configure the total Heat Transfer area into smaller cells. Each cell is served by an independent fan. Thus loss of a single cell has very little impact on the Heat Exchanger performance.

Even Gas & Air Distribution

- The inlet/outlet plenums & cooling fan hoods are designed with aerodynamic considerations & based on CFD analysis to ensure even distribution of gas & air across tubes. This ensures higher efficiency & lower draft losses

- The TMGC uses conservative gas mass flow rates both on gas and air side to achieve high heat transfer coefficients while keeping draft losses low

11 years of Accumulated trust

Request a Price Quote

Let us know your requirements and we will get back to you with the quotation as soon as possible.